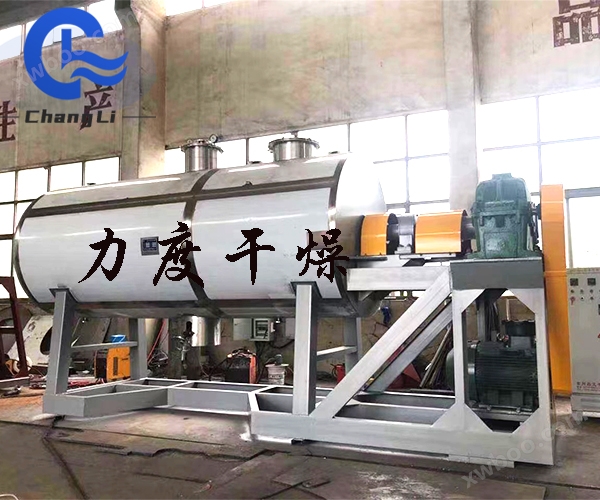

Sodium carbonate rake dryerMaterial Overview

Sodium carbonate is an inorganic compound with the chemical formula Na2CO3 and a molecular weight of 105.99. It is also known as soda ash, but classified as a salt rather than a base. In international trade, it is also known as soda ash or alkali ash. Sodium carbonate is a white powder, odorless and tasteless, easily soluble in water. The aqueous solution is strongly alkaline and can absorb moisture and form lumps in humid air, partially turning into sodium bicarbonate. The production methods of sodium carbonate include the combined alkali production method, ammonia alkali method, Lu Blan method, etc., and can also be refined by processing natural alkali. It is an important inorganic chemical raw material, mainly used in the production of flat glass, glass products, and ceramic glazes. It is also widely used in daily washing, acid neutralization, and food processing.

Sodium carbonate rake dryerprinciple

Vacuum rake vacuum dryer, also known as rake vacuum dryer, is a dynamic conduction type vacuum drying equipment. With the extension of the application of vacuum rake dryer, a series of specialized variant equipment have been developed, including shaft heat vacuum rake dryer, vacuum blade dryer, vacuum screw belt dryer, etc. The vacuum rake dryer adopts two heating methods: jacket heating and jacket with hollow core shaft and rake arm joint heating. It is suitable for drying and solvent recovery processes of loose materials that are prone to agglomeration and agglomeration during the drying process under vacuum conditions. The vacuum rake dryer is generally equipped with a condenser, solvent receiving tank, vacuum pump, control cabinet, etc. Hot water, thermal oil, steam and other heating methods can be selected according to the process conditions. It can also be combined with concentration equipment and other devices for special purposes.

Sodium carbonate rake dryerEquipment structure:

The tank body of the vacuum rake dryer is cylindrical, and the vacuum rake dryer is composed of a vacuum tank body, a mixing shaft, an end cover, a bracket, a motor, a reducer, a control cabinet, etc.

Vacuum tank: It is a jacket wall heat transfer type, and its upper part is equipped with a vacuum filtration interface (connected to a mixed heat stainless steel sintering vacuum filter), a material inlet (used for vacuum feeding of liquid materials), a manhole (used for equipment maintenance and solid material input), a heat medium inlet and outlet, a temperature gauge pipe mouth, a pressure gauge pipe mouth, etc.

Mixing shaft: There are two types of mixing shafts: conventional (non heating) and hollow core. The hollow core mixing shaft is equipped with a sleeve inside for the entry and exit of heat medium in the shaft and rake arm. The rake arm is welded to the mixing shaft, and there is a rake plate (also known as a scraper plate) with an inclined angle above the rake arm. The rake plate near the cylinder is used to clean the material attached to the cylinder wall during the rotation process, which is beneficial for material mixing and heat conduction.

Rotary seal: The rotary seal between the shaft and the end cover can be equipped with packing seal, mechanical seal and other types according to material and process requirements.

End cover: equipped with a mirror, rotating seal, bearing seat, etc. In addition to observing the internal condition, the mirror can also choose to insert or remove a striking rod from the mirror mouth according to the characteristics of the material.

The rack is a component that sets up the transmission device of the vacuum rake dryer, usually made of channel steel or thick walled square tube.

Manhole: Generally, a quick opening press vacuum manhole is used for solid material input and internal equipment maintenance. For equipment that may undergo positive pressure operation, standard vacuum manholes should be selected.

Vacuum filter; The general configuration is a mixed heat stainless steel sintered vacuum filter, with heat tracing and insulation on the outside of the filter housing to prevent the condensation and reflux of evaporated solvents. The filter material is a stainless steel sintered filter or a filter made of multi-layer stainless steel sintered plates, which can be disassembled and cleaned for easy cleaning. Due to the fact that most materials only exhibit peak dust carrying waves after the evaporation of most solvents, the use of pulse blowback has little effect on solvent recovery. Therefore, vacuum filters are often equipped with compressed air or nitrogen pulse blowback for online dust cleaning based on material characteristics and process requirements. In process design and equipment procurement, the functional properties of vacuum filters can be selected based on material characteristics and process requirements.

Vacuum discharge valve: composed of a valve seat, sealing gasket, valve plate, lifting cylinder (or manual screw), and locking bolt. The lifting cylinder of the top ZPG vacuum rake dryer is powered by compressed air and equipped with a self-locking control valve, which can automatically lock the open or closed state to prevent valve opening or closing failure due to sudden compressed air supply failure. For the vacuum rake dryer used in large-scale combination devices, in order to facilitate the connection of materials through screw, vacuum suction and other methods, the vacuum discharge valve is often used in a self controlled combination.

Transmission mechanism: composed of a motor and a reducer, the reducer is directly connected to the mixing shaft through a coupling, and the reducer and motor are driven by a belt, which can avoid damage to the mixing shaft or seal when unforeseen debris enters the tank and causes blockage between the mixing blade and the tank without being detected. To ensure the continuous effectiveness of the rotary seal, variable frequency speed regulation is generally used for the transmission motor.